|

Process

Carved and Etched Glass

|

| Our work, the etched and

carved glass, is done primarily by sandblasting. Essentially, the

process involves taking a piece of plate glass, covering it with a

stencil material, transferring the design, cutting the stencil and then

sandblasting the exposed surface of the glass as it is revealed by

peeling off the cut pieces of the stencil. It is actually more complex

than that and I will go through each step in more detail.

|

|

In any project, the art work comes first. I

start with a design consultation during which we look at past projects,

look through my design books, talk with the client to get a feel for

their likes and dislikes and the environment that the work will

eventually go in. I will do several compositional sketches in scale

from which the client will select. Then we will talk about techniques

for rendering the design in the glass.

|

|

|

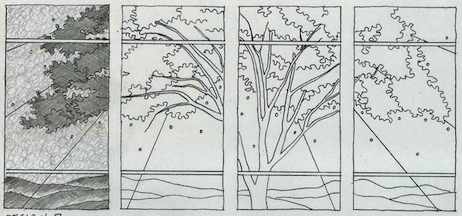

After the design has been selected and

refined and the techniques decided upon, the next step is to do an

enlargement at 1/3 to 1/4 scale, adding details and cleaning up the

drawing. |

|

|

|

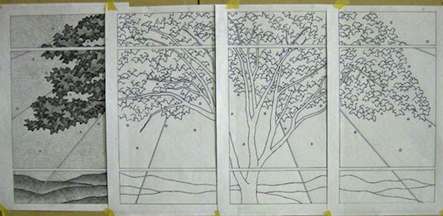

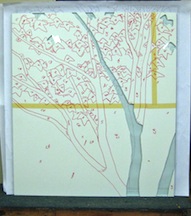

Finally, it is enlarged to full size and a

new full size drawing is traced. When the drawing is complete we take

it to a reprographics company and get copies made in the reverse. This

is necessary because the clear smooth side is actually the viewing side

so the design will have to be etched in the reverse.

|

|

|

|

The first step in working on the glass is to

protect the reverse side from 'back blast' and scratches while the

piece is being worked on and moved around. To this end, we cover the

reverse side, which is actually the front side, with a thin clear

plastic tape.

|

|

|

|

Then we flip it over and cover the worked

side with the stencil material, a thick vinyl that is adhesive on one

side. Once the glass has been covered with the stencil material, we

take one of the copies of the drawing and use spray adhesive to adhere

it to the vinyl covered glass.

|

|

|

|

When the drawing is adhered to the vinyl

covered glass, it is time to cut the stencil. For this I use a hobby

knife with a #11 blade. Essentially, I am tracing the design with the

knife, cutting through both the paper pattern and the vinyl at the same

time.

|

|

|

|

The second copy of the drawing will become

the diagram. The diagram is what tells Marc, who does the actual

etching and carving, the sequence for blasting, for peeling off the cut

parts of the stencil.

|

|

|

|

Once the stencil is cut, Marc transfers the

numbering from the diagram onto the stencil for easy reference in the

blast booth.

|

|

|

|

When the stencil is complete and the

numbering transferred, Marc takes the panel into the blast booth. This

is a small room since most of the panels we work on are too large to

fit into a blast cabinet. Marc wears a separate air supplied helmet

that due to the air pressure does not allow the dust to infiltrate into

his breathing space. This is essential since breathing the dust can

have disasterous effects on your health. He will peel off all the

number ones on the stencil and carve them to the appropriate depth,

then the twos, then the threes, etc until all the blasting is finished.

|

|

|

|

|

|

|

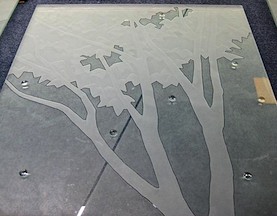

Sometimes, privacy is

required in a finished piece. When this is a requirement of the work,

the next step is to clean off all the stencil material still remaining

on the glass, cleaning it and then covering it again with a clear

stencil material.

|

|

|

|

|

Then I cut a new stencil

around the edges of the carved and etched design staying about 1/16"

away from the etching.

|

|

|

|

|

I remove the clear tape,

which is now covering the etched and carved design elements, to expose

the clear glass in the background. To obscure the background of the

design, or in some cases, add just a different tone and texture to a

design, I use a flouride salt based cream on the exposed clear glass

that gives a more satin etched look. The end result is a sandblasted

carved and etched design with a clear line around it and a satin opaque

background.

|

|

|

|

|

|

|

|

One of the other techniques

we use is applying clear textured glass and bevels and jewels to the

surface of the glass. This is a time consuming and complicated process

that involves using a UV setting optically clear adhesive. We also

create different textures in the sandblasting by using glue as a resist

applied in various techniques as well as blasting through open weave

fabrics for certain effects.

|

|

|

|

|

Finally, when all the etching

and special techniques are done, we apply a sealer to the etched

surface to help prevent dirt and oils from being absorbed by the etched

surface.

|

|

|

|

|

|

For more pictures and

information about this installation go here.

|

|

|

|

|